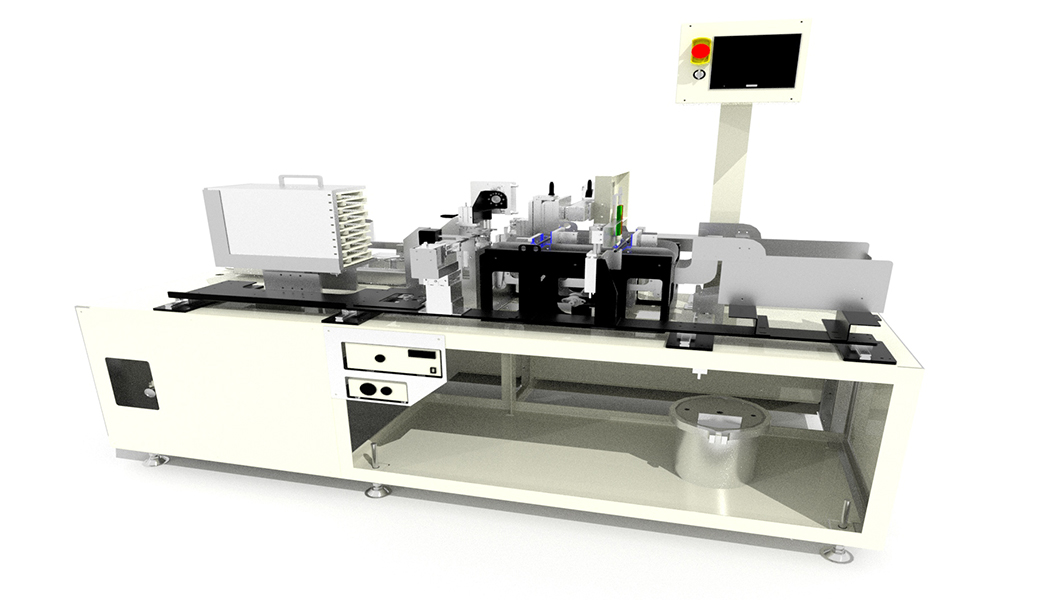

Shaft assembly equipment overview

Our shaft assembly equipment is cutting-edge industrial equipment that automates the process from parts supply to assembly.

Replacing manual assembly processes with automated systems significantly improves production line efficiency.

The introduction of this equipment will minimize manual labor and reduce the physical burden on workers, while achieving stable, high-quality product production. Furthermore, by shortening production cycle times and eliminating human error, it will also contribute to reducing manufacturing costs.

Our shaft assembly equipment meets the automation needs of the manufacturing industry and is the ideal solution for factory automation in the coming era.

Key points of shaft assembly equipment

-

POINT1

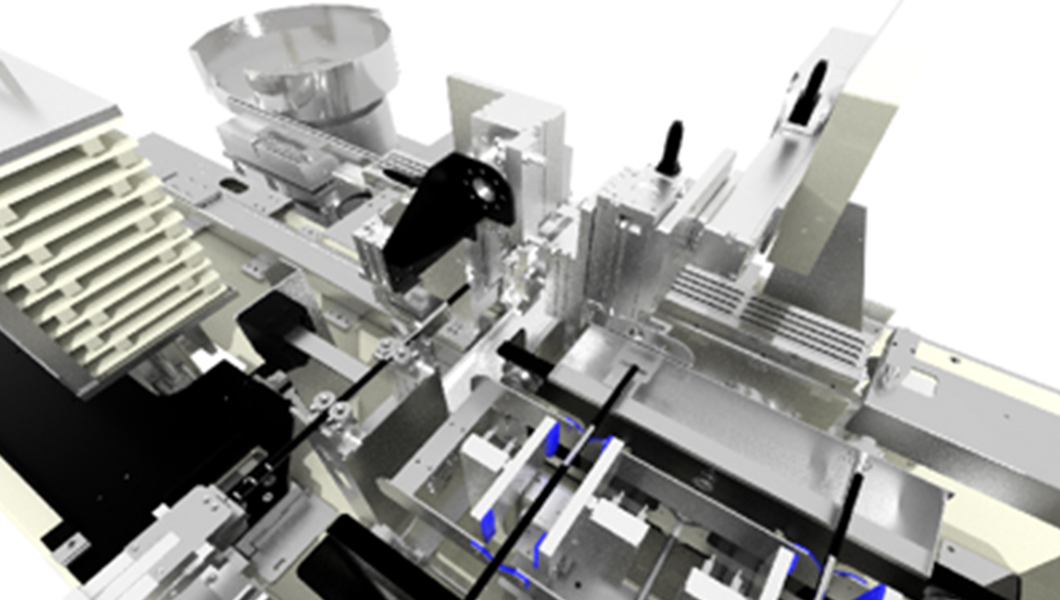

Automatic Supply System

Employing the latest parts feeder technology, we provide a stable and continuous supply of parts of various sizes and shapes, minimizing interruptions to the production line and achieving a highly reliable supply mechanism that maximizes uptime.

-

POINT2

High-precision assembly

High-sensitivity sensors and unique control algorithms ensure precise shaft positioning, ensuring stable, high-precision assembly work that meets strict quality standards and significantly reducing the rate of defective products.

-

POINT3

Space-saving design

The compact chassis design reduces the installation area compared to previous models, allowing for efficient use of limited factory space and providing excellent installation flexibility to flexibly accommodate layout changes.

-

POINT4

Improved operability

The intuitive touch panel interface makes it easy to operate, even for those without specialized knowledge. It simplifies setting changes and status monitoring, helping to reduce operator training time and prevent human error.

Application Examples

- Automotive parts manufacturing Ideal for high-precision assembly of engine drive systems and powertrain shaft parts. In the automotive industry, where durability and precision are required, this machine achieves stable production that reliably meets quality standards and meets the strict delivery deadlines and quality demands of automakers.

- Electronic Component Manufacturing This automates the assembly process of minute electronic components such as small motors and actuator shafts. It is also compatible with clean room environments, achieving both stable quality and productivity in the manufacture of electronic components, which require high levels of cleanliness.

- Precision equipment manufacturing We handle shaft assembly for precision equipment that requires high accuracy, such as medical equipment and measuring instruments. In the manufacturing of products that require precision control at the micron level, we efficiently produce products of stable quality that eliminate human error.

About our products

Please feel free to contact us with any questions or concerns.

Please contact us.