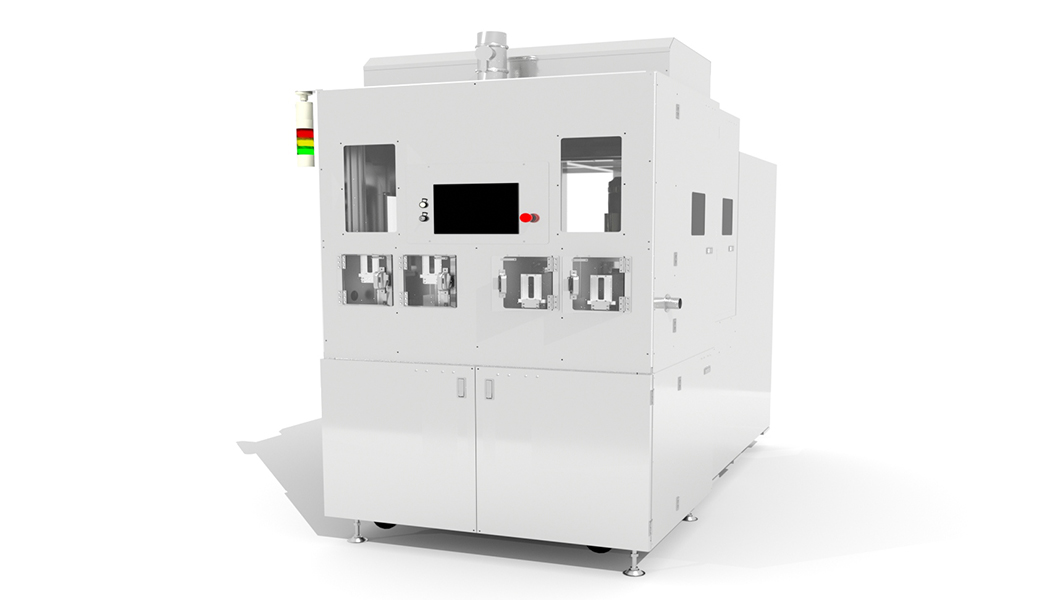

Material handling equipment overview

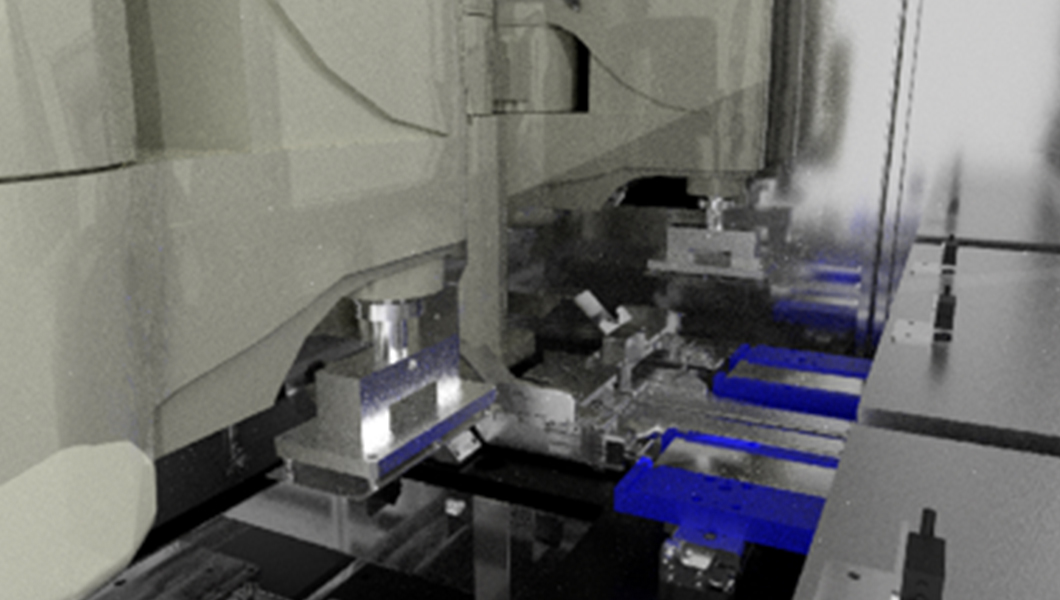

Our material handling equipment is an innovative material handling system that utilizes high-precision SCARA robots.

By fully automating the loading and unloading of parts into and from aluminum cases, waste in the manufacturing process is reduced, resulting in significant efficiency improvements and labor savings on the production line. High-speed, accurate operation contributes to shortening production cycle times and stabilizing quality. It can also flexibly handle high-mix, low-volume production, and can be used for preventive maintenance and production analysis. Its space-saving design makes it easy to incorporate into existing lines, making it a powerful solution for improving productivity and resolving labor shortages in the manufacturing industry.

Key points of material handling equipment

-

POINT1

High-precision transport

The SCARA robot achieves high-speed, high-precision pick-and-place operations, maximizing production efficiency with stable quality and processing speed.

-

POINT2

Supports a variety of workpieces

You can select an end effector that matches the size and shape of the workpiece. This allows for flexible handling of a wide range of products, increasing the versatility of your production line and maximizing the value of your capital investment.

-

POINT3

Inline support

It achieves seamless transport in conjunction with the conveyor line. Smooth linkage with upstream and downstream processes minimizes time loss between processes and improves the efficiency of the entire production line.

-

POINT4

Space-saving design

The compact robot arm minimizes installation space, allowing for effective use of limited factory space and easy layout changes, contributing to the optimization of manufacturing sites.

Application Examples

- Transporting engine parts and electrical components in automotive parts manufacturing This system realizes precise transport of engine components and electrical modules on the automotive manufacturing lines. Its high repeatability dramatically improves the production efficiency of automotive parts that meet strict quality standards.

- Transporting precision equipment and semiconductor parts in electronics manufacturing Ideal for transporting precision electronic parts and semiconductor devices that require micron-level positioning accuracy. Cleanroom compatible models are also available, providing powerful support for the manufacturing process of high-quality electronic devices.

- Conveying packaged foods and ingredients in the food processing industry This food-specific model complies with hygiene standards and enables the safe and efficient transport of packaged foods and raw materials, reducing the risk of foreign matter contamination and improving productivity and safety on food production lines.

- Conveying small metal parts in the metal processing industry The highly durable design allows for high-speed transport of heavy metal parts. It also improves the efficiency of inter-process coordination, such as deburring and surface treatment, and shortens production cycle times in the metal processing industry.

About our products

Please feel free to contact us with any questions or concerns.

Please contact us.