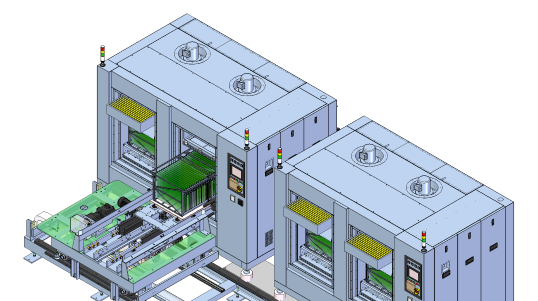

N2 BOX furnace overview

The N2 BOX furnace is a device that uses nitrogen to efficiently dry and bake materials while preventing oxidation.

Ideal for processing products that must avoid oxidation or deterioration, stable temperature control in an inert atmosphere ensures a high-quality finish. Used in a wide range of industrial fields, including electronic components, metal materials, and chemical products, it plays an important role in the manufacturing process of precision parts and high-purity materials. Customizable temperature ranges and processing capacities make it a reliable solution that can flexibly meet your manufacturing needs.

Key points of N2 BOX furnace

-

POINT1

Antioxidant

Treatment in a nitrogen atmosphere suppresses oxidation and discoloration, maintaining the quality and durability of products. It is particularly effective when treating highly sensitive materials and precision parts.

-

POINT2

Uniform drying performance

Uniform temperature control ensures consistent finishes. This allows for uniform heat treatment across the entire product, minimizing quality variations and ensuring high reproducibility.

-

POINT3

Energy-saving design

Optimized nitrogen consumption reduces operational costs. An efficient heat circulation system and thermal insulation maintain high throughput while reducing energy consumption.

-

POINT4

Concentration can be controlled during operation (heating)

This allows for concentration control during heating, which was previously impossible. Real-time monitoring allows for adjustment of the atmosphere during the process, enabling more delicate control of processing conditions.

Application Examples

- Drying and baking while preventing oxidation for electronic components and semiconductors This prevents performance degradation due to oxidation in the manufacturing process of precision electronic circuits and sensor parts, supporting the manufacturing of highly reliable products.It also supports the manufacturing of semiconductors, which are becoming increasingly miniaturized.

- Anti-oxidation treatment for metal materials during degreasing and sintering In the sintering process of metal powder metallurgy and special alloys, it suppresses surface oxidation and maintains high-purity metal properties, contributing to quality improvement in the manufacturing of fine metal structures.

- Drying of lithium-ion battery components for battery and energy-related applications During the drying process for lithium-ion battery electrode materials and separators, we prevent impurities from being mixed in and provide an environment that maximizes battery performance, achieving both safety and performance.

About our products

Please feel free to contact us with any questions or concerns.

Please contact us.