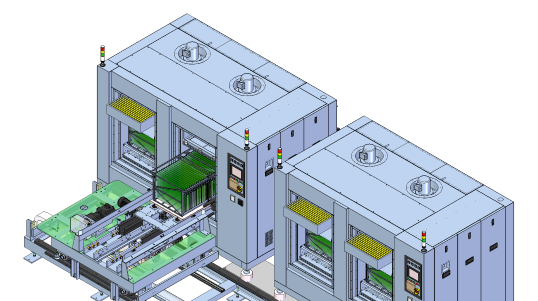

Drying furnace + material handling equipment overview

Our "drying furnace + material handling equipment" is an integrated system that fully automates everything from rack transport to the drying process.High-precision transport control and uniform temperature management minimize quality variations while reducing the risk of product damage.

This solves the problems of uneven quality and poor work efficiency that occurred in conventional manual processes, and achieves a stable, high-quality finished product.

Key points of drying furnace + material handling equipment

-

POINT1

Automatic transport system

The automatic supply and removal of racks significantly reduces the burden on workers. It prevents human error caused by repetitive work and improves productivity. It also contributes to ensuring worker safety and leads to an improved working environment.

-

POINT2

Multi-tier rack compatible

It is possible to efficiently process large volumes of workpieces even in limited factory space. By effectively utilizing vertical space, it maximizes production efficiency per installation area, achieving high processing capacity despite its compact size.

-

POINT3

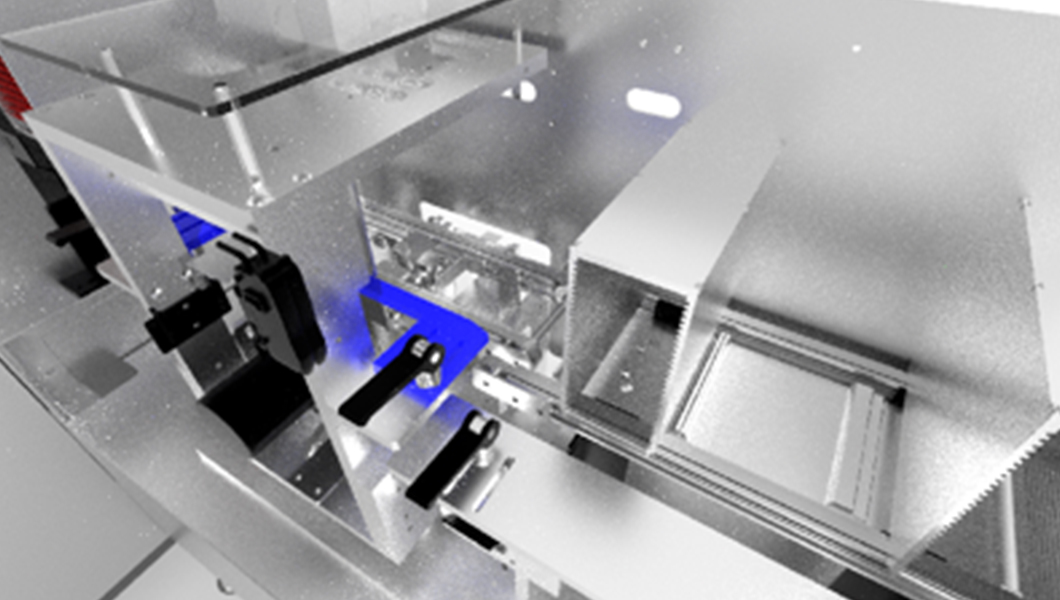

High-precision temperature control

Equipped with a control system that ensures uniform temperature in each zone. This suppresses temperature variations and contributes to stabilizing product quality. Monitoring by various sensors and advanced PID control minimize deviation from the set temperature.

-

POINT4

Clean room compatible design

The design meets the high level of cleanliness required for semiconductor manufacturing. The structure and materials are selected to suppress dust generation, eliminating the risk of product contamination and supporting high-quality product manufacturing.

Application Examples

- Power semiconductor drying process It is ideal for drying parts and substrates after cleaning in power semiconductor manufacturing. Precise temperature control allows for uniform drying of delicate semiconductor elements, contributing to improved quality and reliability. Flexible operation is possible, allowing for high-mix, low-volume production.

- Hardening treatment for protective films and adhesive processes It is suitable for protective coatings on various electronic components and for curing adhesives. It achieves stable curing characteristics in a uniform temperature environment, improving product durability and reliability. Program control allows it to handle different curing conditions, making it suitable for a wide range of products.

- Reliability testing in high temperature environments It can be used for temperature testing to evaluate a product's heat resistance and long-term reliability. By maintaining a stable high-temperature environment for a long period of time, it is possible to evaluate products under strict conditions. The test data also contributes to strengthening the quality control system.

About our products

Please feel free to contact us with any questions or concerns.

Please contact us.