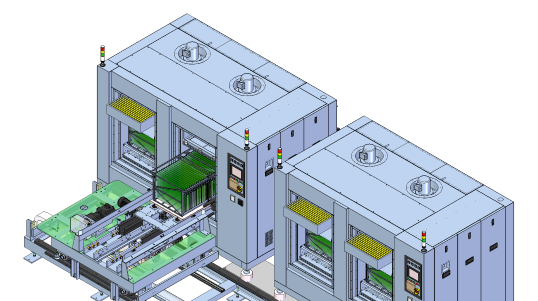

Drying oven overview

Our drying oven is a device that realizes stable temperature control and a highly efficient drying process. Our unique air circulation system maintains uniform temperature distribution within the chamber, making it possible to heat and dry workpieces under constant conditions while continuously transporting them.

The adoption of a continuous processing method achieves a significant improvement in productivity compared to batch processing, while also contributing to the stabilization of product quality.

Key points about drying ovens

-

POINT1

Highly efficient continuous processing

By processing workpieces continuously, production efficiency is significantly improved. Processing time is reduced compared to batch processing, optimizing personnel allocation and maintaining consistency on the production line.

-

POINT2

Uniform drying performance

The temperature distribution inside the furnace is precisely controlled. In a thermal environment with minimal temperature variations, the entire product is dried evenly, achieving high quality stability. Even workpieces with complex shapes can be dried evenly.

-

POINT3

Various heating methods

The optimum heating method can be selected for the application and object from a variety of heating methods, including hot air, far infrared rays, UV, microwaves, etc. By combining the optimum heating method according to the different material properties and required drying quality, a wide range of industrial needs can be met.

-

POINT4

Energy-saving design

The use of high-performance insulation materials and an exhaust heat recovery system minimizes energy consumption, significantly reducing operating costs compared to conventional models while also contributing to a reduced environmental impact.

Application Examples

- Drying of printed wiring boards after resist application This system achieves uniform drying after applying photosensitive resist in the electronic circuit board manufacturing process. Precise control of the temperature profile improves the precision of fine pattern formation, increasing the yield of high-density mounted circuit boards.

- Drying of automotive parts and painted products Efficient drying process for painted automotive parts and various industrial products. Uniform temperature distribution stabilizes the quality of the paint film, achieving both durability and aesthetics. Continuous processing is possible for large and small parts, contributing to the efficiency of the production line.

- Removing moisture from film and sheet materials Moisture control in the manufacturing process of resin films and various sheet materials. Precise temperature control and appropriate air volume adjustment achieve optimal drying conditions while preventing deformation and quality deterioration of the material. High productivity through continuous processing makes it suitable for mass production.

About our products

Please feel free to contact us with any questions or concerns.

Please contact us.