Spray Coater Overview

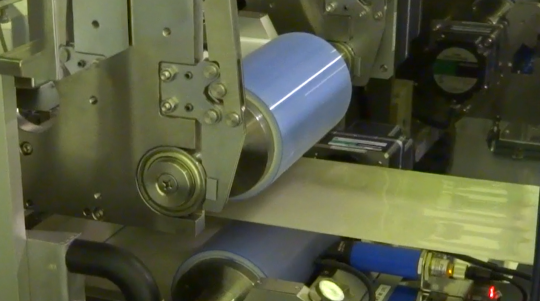

Our spray coaters are advanced equipment for applying uniform, high-quality coatings to a variety of industrial substrates.

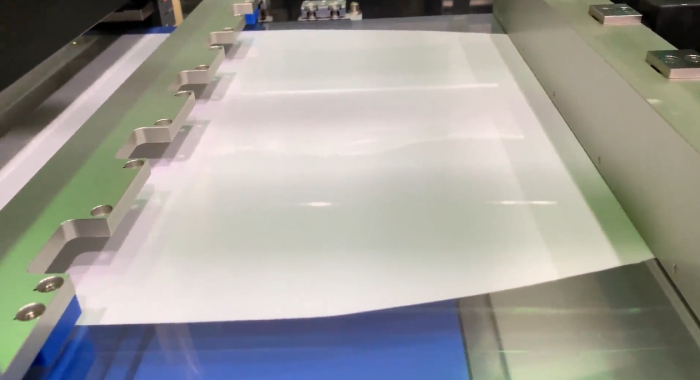

The precise application of fine particles achieves a smooth, even finish, contributing to improved product quality and maximizing production efficiency.

It can be used in a variety of industrial fields to improve product durability, functionality, and aesthetics.

We offer spray coating solutions for a wide range of applications, from precision machinery parts to large industrial components.

Key points of spray coaters

-

POINT1

Uniform application performance

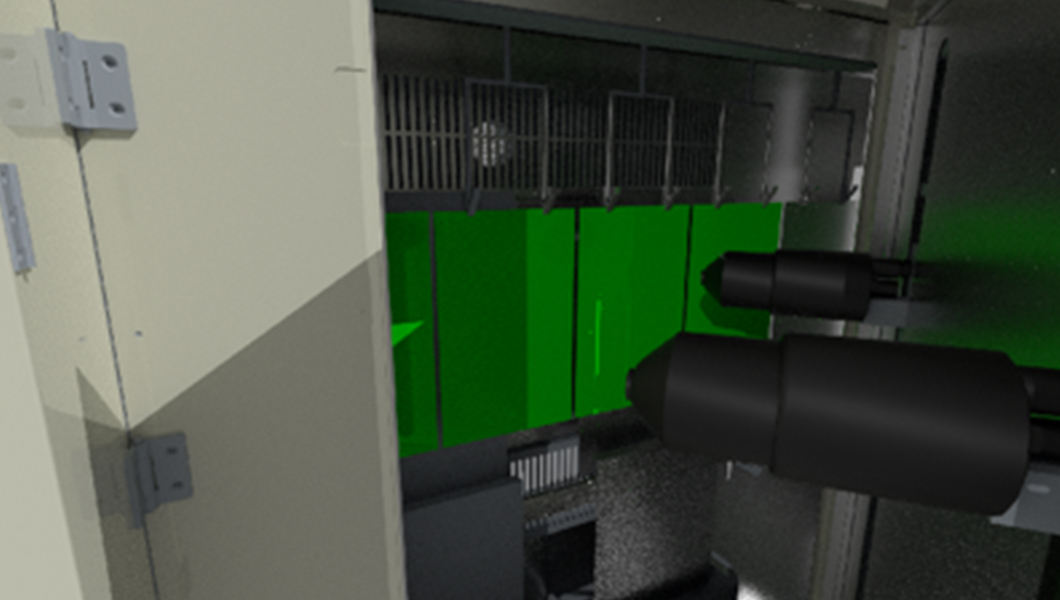

Cutting-edge atomization spray technology ensures uniform coating across the entire substrate. Our unique nozzle design and spray control system enable uniform coating even on products with complex shapes, contributing to consistent product quality.

-

POINT2

Compatible with a wide variety of materials

It can be applied to a wide range of materials, including metals, plastics, glass, ceramics, etc. By setting application parameters to suit the characteristics of each material, optimal adhesion and durability can be achieved, meeting the coating needs of all industrial fields.

-

POINT3

Precise control possible

Equipped with an advanced control system that can finely adjust spray pattern, coating amount, spray speed, etc., it achieves optimal coating conditions, directly leading to improved product properties.

-

POINT4

Energy-saving and environmentally friendly

The highly efficient spray system minimizes paint waste, reducing both material costs and environmental impact. The introduction of a collection system allows for the reuse of excess paint, supporting the creation of a sustainable manufacturing process. This environmentally conscious design also contributes to the reduction of VOC (volatile organic compound) emissions.

Application Examples

- Resist coating for printed wiring boards It uniformly coats resist material, which is essential for protecting and forming precision electronic circuits. It also supports fine patterns, contributing to improved manufacturing quality for high-density mounting boards.

- Coatings to improve durability of automotive parts It is used to prevent rust on metal parts and improve the weather resistance of plastic parts, forming a high-quality protective layer that can withstand use in harsh environments and extending the life of parts.

- Surface treatment for medical equipment and precision instruments We apply special coatings uniformly to enhance biocompatibility and sterilization, and achieve advanced functionality such as controlling the coefficient of friction and imparting antifouling properties to precision parts.

- Functional coating for various films and glass Ideal for anti-reflection treatment of optical films and water- and oil-repellent treatment of touch panel glass. Forming a uniform thin film provides functionality while maintaining high transparency.

About our products

Please feel free to contact us with any questions or concerns.

Please contact us.