assignment

Semiconductor industry: Issues with the liquid application process between plastic films

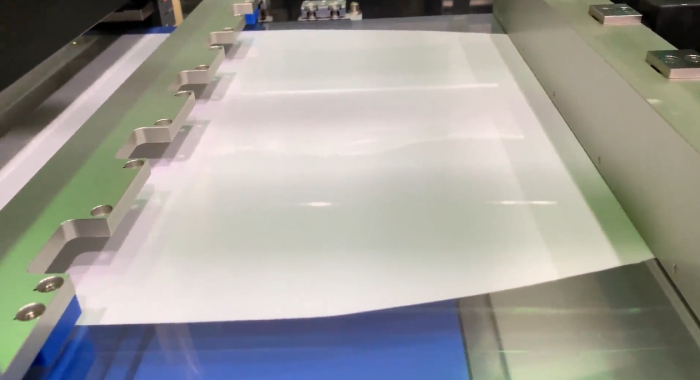

We wanted to stack two plastic films and apply a film-forming material (liquid) evenly between the films, but we encountered the following problems.

・The coating must be applied at the exact timing when the liquid becomes uniform, and misalignment or variations in speed can easily cause unevenness or bias.

・If the film meanders or the tension is not consistent during transport, it will affect the spreading of the coating liquid.

・There are layout restrictions as we want to reuse existing equipment for the drying oven used after coating.

Examples and Uses

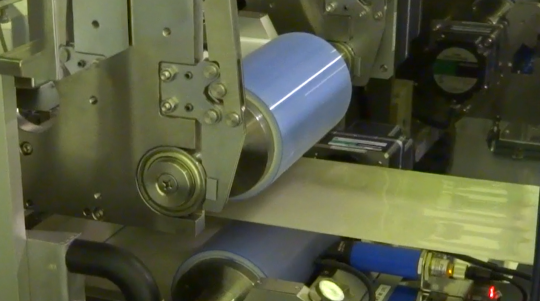

① Create a system that allows the coating liquid to accumulate evenly

・Designed to provide an optimal clearance (gap) between the roll and the sheathing, allowing the coating liquid to be uniformly distributed.

This structure stabilizes the thickness and distribution of the liquid, reducing the need for precise alignment of the bonding position.

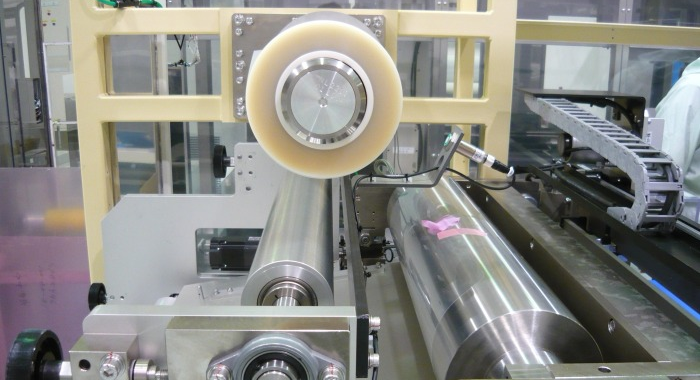

②Prevention of overfeeding by tension control

- Introduces a torque limiter and other counter torque control mechanisms to prevent overfeeding of plastic film.

This prevents meandering and tension inconsistencies during transport, reducing the impact on the spreading of the coating liquid.

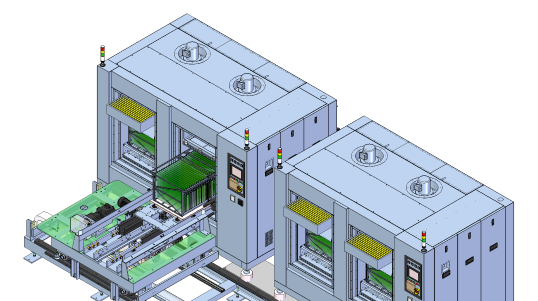

3) Cost reduction through design compatible with existing drying ovens

・The drying oven is designed flexibly so that existing equipment can be used as is.

No need for new installation, avoiding large capital investment

*We can also install a new drying oven if necessary.

Product Introduction

Our roll coaters are the optimal solution for achieving uniform, high-quality coating. They enable precise coating on a variety of substrates, including film, paper, metal, plastic, and glass, providing uniformity and reproducibility not achievable with conventional coating methods. With the industry's highest level of coating precision and production stability, they contribute to improved product quality and significant improvements in production efficiency.

See product information for this case study and usage image

About our products

Please feel free to contact us with any questions or concerns.

Please contact us.